Driving battery recycling efficiency

RECYCLING SERVICES

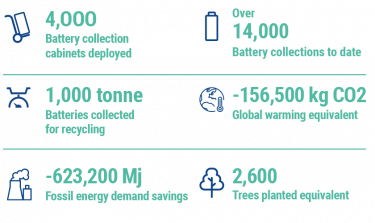

Superfy supporting Ecobatt with their nationwide battery recycling programme, reducing operational costs for 14,000 collections of 1,000 tonnes of batteries across more than 5,000 collection points

Ecocycle’s recycling service

Ecocycle is Australasia’s most experienced mercury recovery and recycling company. Ecobatt, the battery collection, sorting and processing arm of Ecocycle’s e-waste business, is focused on keeping batteries and other hazardous waste out of landfills. It recycles all types of batteries to safely recover mercury, lead, silver, nickel, cobalt, steel, lithium and plastic. The battery stewardship initiative in Australia has encouraged Ecobatt to implement a national battery recycling programme, which for a country as large as Australia, was an ambitious project.

The need to leverage partners and technology

Early on, they recognised the need to partner with retail grocery chains to ensure the recycling process for everyone was as convenient as possible.

The next challenge to overcome in a nationwide progamme was to be able to manage the collections as efficiently as possible. With bin locations varying in range from close together in a metro location to widely spread out into remote regions, it was going to be difficult to manage collections without some form of automation. Key to this process was knowing when the bins needed to be collected and to be able to optimise the route planning for multiple truck drivers who can make up to 25 different collections a day. In addition, safety concerns needed to be addressed given the hazardous nature of multiple batteries in a bin and the potential to catch fire

”Superfy has supported us by reducing operational costs with added efficiencies in battery collection and vehicle routing.”

Nick Dodd

General Manager,

Ecobatt

Adopting the Superfy platform for fill level monitoring, dynamic routing and safety

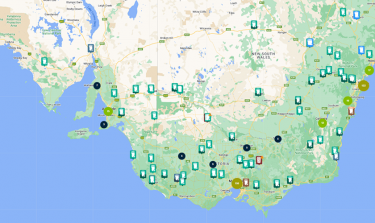

With Superfy, Ecobatt found an ideal partner, to manage a number of key requirements for the recycling programme. As Nick Dodd, General Manager at Ecobatt explains, “The ability to manage thousands of smart bins around Australia has been the greatest benefit, it’s literally an impossibility to do economically without some sort of technology. We know that Superfy has supported us by reducing operational costs with added efficiencies in battery collection and vehicle routing.”

“The Superfy platform gives us the ability to visualize on our maps what bins are in that area, the fill level status of them, as well as the bins along the route in that area. It is pretty intuitive, and has been wonderful for us and has allowed us to transform our business

quite dramatically.”

“The ability to manage thousands of smart bins around Australia has been the greatest benefit, it’s literally an impossibility to do economically without some sort of technology.”

Nick Dodd

General Manager,

Ecobatt

-

The asset management module is where the allocation of bins is implemented, along with a visual view of all bins, their fill level and temperature status and various other statistics and alert settings.

-

Given the large number and dispersed location of bins deployed, the routing module was a key requirement for Ecobatt. The team create multiple new routes on a daily basis and being able to automate and send to the drivers, to follow on their mobile phone app was a significant operational improvement. “The routing part of the app allows us to generate routes and then push them out to our drivers on their mobile phones so the drivers don’t need to be in an office.”

-

The driver app is also being used to enhance workflow management. Checklists on the app ensure all collections are carefully managed and a picture capture feature enables the monitoring of branding, cleanliness and overall maintenance of the bins with instant reporting and feedback.

-

The variety of reporting and visual graphics of the reporting module have enabled Ecobatt to anticipate collections and ‘false full’ fill levels, using the predictive analytics and historical data reporting.

“I feel like Superfy are our partner and that’s the important thing, they have held our hand the whole way along, even working out the best place to mount the sensors in our bins.”

Nick Dodd

General Manager,

Ecobatt

Truck Driver Experience

Finally, from a safety perspective, all devices include a temperature sensor to monitor for potential fires before they happen to trigger the emergency 24/7 alert notification system.

Truck driver Robbie Walker says “We don’t want to see batteries going to landfill. There is no need for it now,” he says. “We recycle and protect our environment so my grandkids can enjoy this planet. We make it a better place for future generations to play.”

The drive app, produced by Superfy, logs their route daily and provides instructions for sites. Photos are taken at each site, before moving to the next pick-up. He says that after 18 months of working in the field the app is a “great system that works really well.” [1]

[1] https://wastemanagementreview.com.au/in-the-drivers-seat-at-ecobatt/

The nationwide rollout

Ecobatt have deployed close to 4,000 battery collection cabinets to date and have made over 14,000 collections, around 1,000 tonnes of batteries for recycling. This equates to a saving in carbon dioxide (CO2) emissions of over 156,000 kg CO2. [2] The programme is growing in popularity as public awareness about the importance and convenience of battery recycling increases. Ecobatt is an accredited collector and recycler for B-cycle, Australia’s innovative battery stewardship scheme and is a major collector. Ecobatt is a valuable enabler of Australia’s long term strategic goals of zero battery waste to landfill and a battery recycling industry that is self-sustaining, profitable and growing.

Ecobatt take pride in doing things differently and efficiently and in this regards, the Superfy solution was considered an ideal fit and ahead of the competition. Overall the visual and intuitive navigation of the platform, along with flexibility to meet their requirements and excellent customer service proved an ideal combination to meet Ecobatt’s needs. As Nick summaries, “I feel like Superfy are our partner and that’s the important thing, they have held our hand the whole way along, even working out the best place to mount the sensors in our bins.”

The success of this programme is opening up opportunities for Ecobatt in other areas of recycling. Overall, these types of initiatives are not only operationally successful, but environmentally too. Superfy is proud to support Ecobatt’s sustainable, recycling waste management programme.

[2] Visit the Ecobatt Battery Recycling Calculator at https://www.ecobatt.net/battery-recycling-calculator